Despite that Heavy-Duty Vehicles (HDVs) represent a small part of the overall vehicle population (5%) they have been identified as one of the most important contributors to air pollution (33% of the pollutants emitted in European cities).

This is one of the reasons why HDV emissions regulations are becoming more and more stringent worldwide.

Following this trend, Europe introduced the Euro VI standard which includes more stringent emission limits for hydrocarbons, PM and NOx, while for the first time a limit for solid PN emissions was set [4].

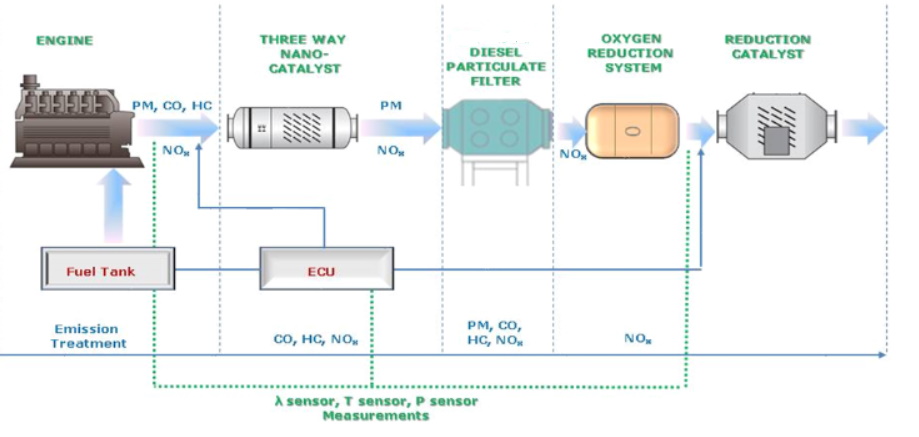

INNOCAT aims to retrofit Heavy Duty vehicles with a Control Emission Catalytic System (CECS) allowing them to meet Euro VI standards. This system will be consisted of a Three-Way Catalyst (TWC), a Diesel Particulate Filter (DPF), an Oxygen Reduction System (ORS) and a Reduction Catalyst (SCR).

The different modules of this CECS (TWC, DPF, ORS) will be mounted in a single metallic canister, with external dimension not bigger than the muffler, making it very easy to retrofit all Euro categories of existing HDVs, even old Euro 0 ones, and can easily be applied to other vehicles such as boats; This catalytic system was first studied and applied for the European project LIFE CAT4HEAVY.

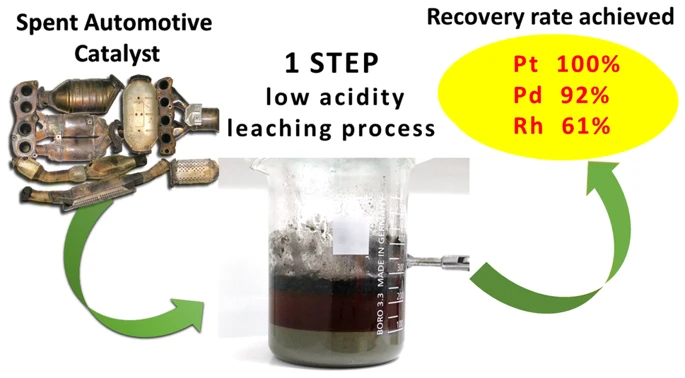

The Three Way Catalyst (TWC) and Selective Reduction catalyst (SCR) of this CECS uses a nanomaterial composition enabling the substitution of up to 67% of PGMs with Copper Nanoparticles as the active catalytic material, hence making the catalyst extremely cheaper compared to state of the art Euro VI DOCs and affordable for HDV retrofitting applications.

This catalyst will also contribute to the initial scope of INNOCAT project, which is an alternative solution to the PGMs utilization.

These TWCs have been fully tested on light vehicles, both in the Centre Research Fiat, in Torino, Italy, against Fiat State of the Art Euro 6 catalyst, and in Real Life Conditions (TRL7), on three cars (Renault Megane, Mini Cooper and Fiat 500). [1]

The Oxygen Reduction System (ORS) will be used in a multi-tubular module formation, where the exhaust gas is fed through the lumen side and CO2 and O2 will permeate across the membrane to the shell side, while total surface area will be adjusted to obtain adequate permeation rate.

In the produced shell side mixture, CO2 and O2 will be present in a molar ratio of 2:1 and it can be either released to the atmosphere or to be used on-board to improve the efficiency of the engine utilising the high O2 content.

The ORS will be placed downstream the diesel DPF system and upstream the Rh-Reduction Catalyst that allows for particulate-free operation of the ORS.